Grafo-Therm Specification

GRAFO-THERM HAS PASSED THE CONDENSATION CONTROL TEST

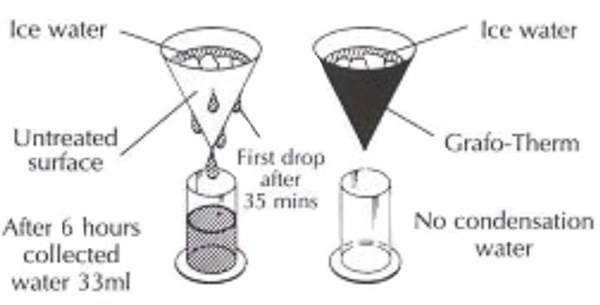

The effect of Grafo-Therm can be proved with a British testing method (ministry of supply SSF B 111).

A cone shaped copper vessel is sprayed on the outside with Grafo-Therm and placed together with an identical untreated cone in a room at 20°and 60 % relative humidity.

Both cones are filled with ice water, RESULT:

What is condensation

Air is a mixture of gases. There is always vapour in the air, and there is more of it when the temperature is high. When the vapour meets a cold surface it condenses into water.

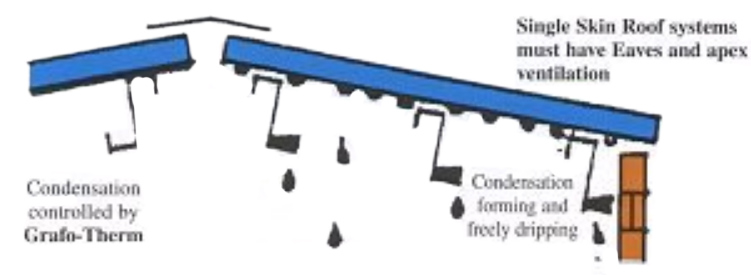

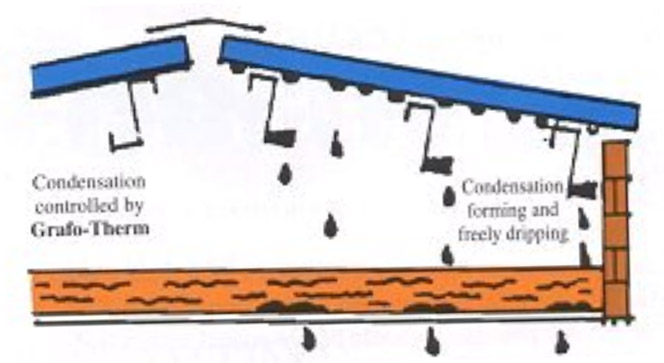

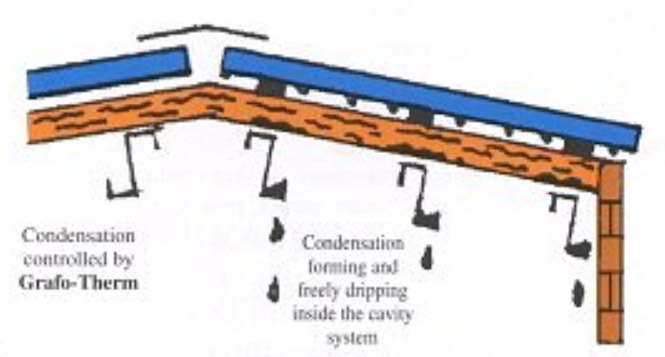

Condensation always occurs when the surface temperature is down to and below the so called dew point. In buildings with a single skin roof system condensation occurs during the quick changes in weather. The surface temperature of a steel roof may due to rain or heat radiation during the night, fall as much as 5° below the inside temperature. These circumstances do not usually last long. The problems caused by condensation can easily be prevented by Grafo-Therm ant-condensation coating.

The Grafo Therm treatment. How does it work

In the dry state Grafo-Therm is an efficient thermal insulant, albeit that a 1.5mm thickness would bot be efficient against heat loss, it does put back the time before dew point occurs, thereby preventing or considerably reducing the periods during which condensation forms. Thereby reducing the amount of condensation formed during any one 24 hour period.

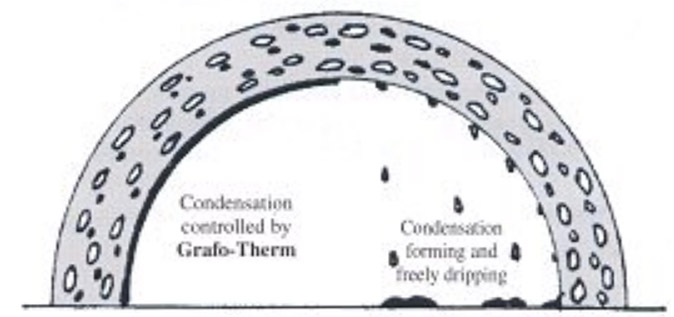

Whenever dew point is reached on the surface coated, condensation will form and this will immediately be absorbed by the coating.

A 1.5mm thickness can absorb and control against dripping up to 1.0 litres moisture per m².

Having absorbed moisture it is most important to effect rapid evaporation and removal from the cavity, when conditions change to drying.

For this Grafo-Therm is superb, for example, when sprayed onto a 1000m² corrugated roof the textured finish of the compound effectively increases the specific drying surface by at least 10 times = 10,000m², on most corrugated sheets this can be increased by 20% to allow for the corrugations – 12,000m² of drying surface.

Grafo-Therm having proven absorption and capillary capabilities assures maximum benefit from this large specific drying surface, enabling fast and efficient cyclic drying.

The releasee properties of Grafo-Therm are faster per thickness and area than competitive materials which rely on greater thickness being applied.

Grafo-Therm offers more than Condensation Control

Grafo-Therm offers more than condensation control.

Grafo-Therm in it’s light grey colour provides an attractive textured surface, in white it provides excellent light reflection.

Grafo-Therm reduces the effect of reverberating noise from steel sheets, and dramatically reduces the noise from wind and rain.

Standard Colours Light grey or white.

Corrosion Protection

Typical areas for application

When free from the damaging effects of condensation the roof systems below are excellent at providing their design function.

When condensation is controlled on the single skin roof sheet, this built up over purlin system is very cost effective in both the short and long term. Grafo-Therm will provide protection for the life of the steel sheets.

Concrete structures such as hardened Aircraft Shelters, Multi Storey Car parks may also benefit from a coating of Grafo-Therm to provide Condensation Control, Light Reflection and Noise dampening.

In most of these buildings it is a mixture of natural ambient temperature, relative humidity and the natural performance of steel or aluminium roof sheets when subjected to the effect of clear night radiation (frost) after they have been used to roof in a single skin application on both insulated and uninsulated buildings.